Educating Our Communities

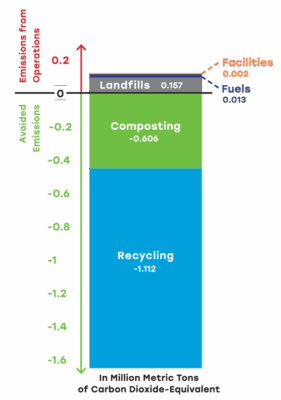

Our Waste Zero education and outreach teams educate and inspire communities to recycle and compost.

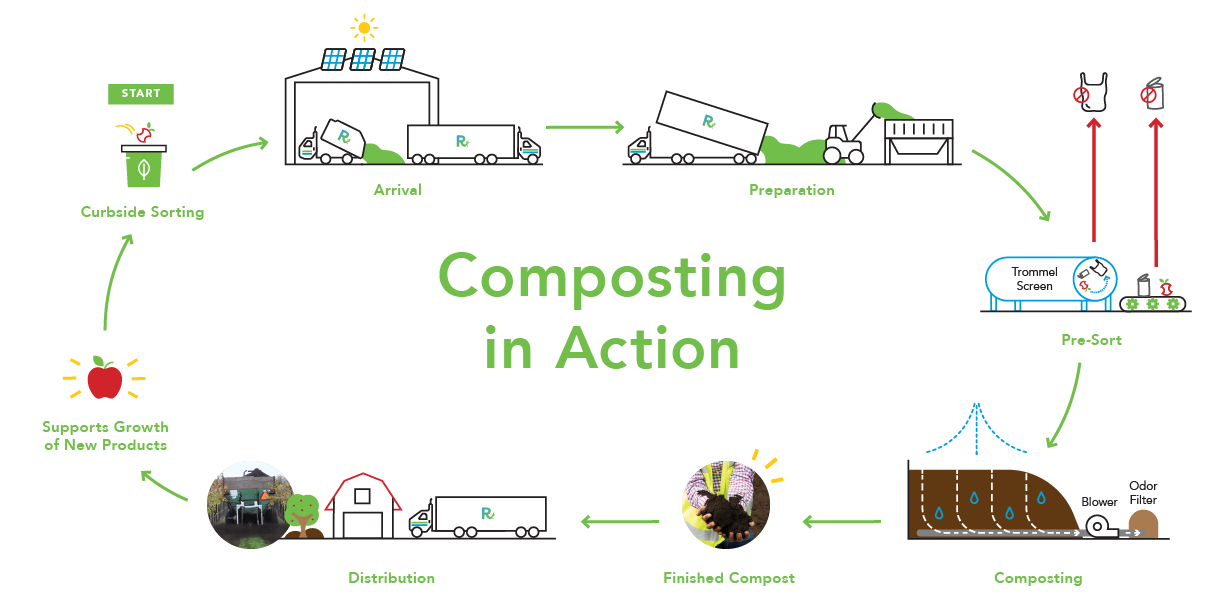

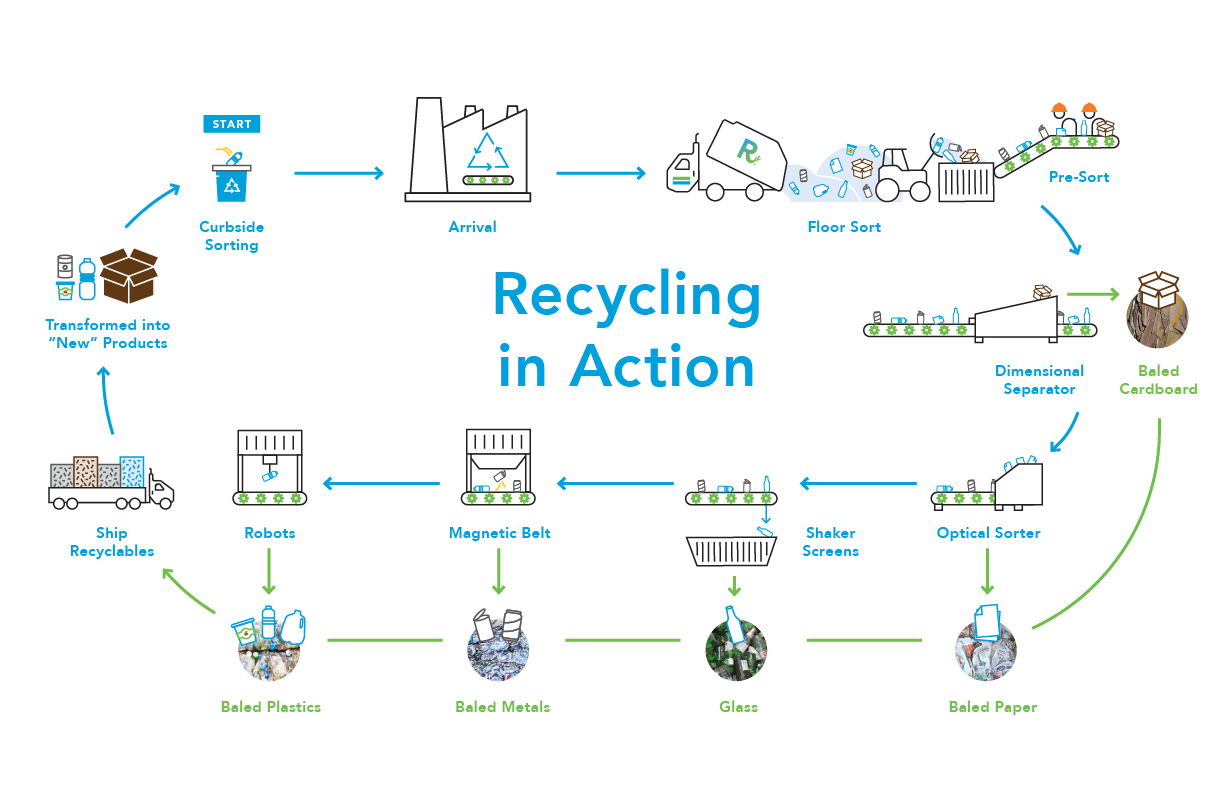

Working closely with local community leaders, Recology Waste Zero teams contribute to our long-term goal of waste reduction. Teams evaluate community needs and educate residents and businesses on recycling and composting best practices through site visits and consultations, trainings and presentations, facility tours, and more.

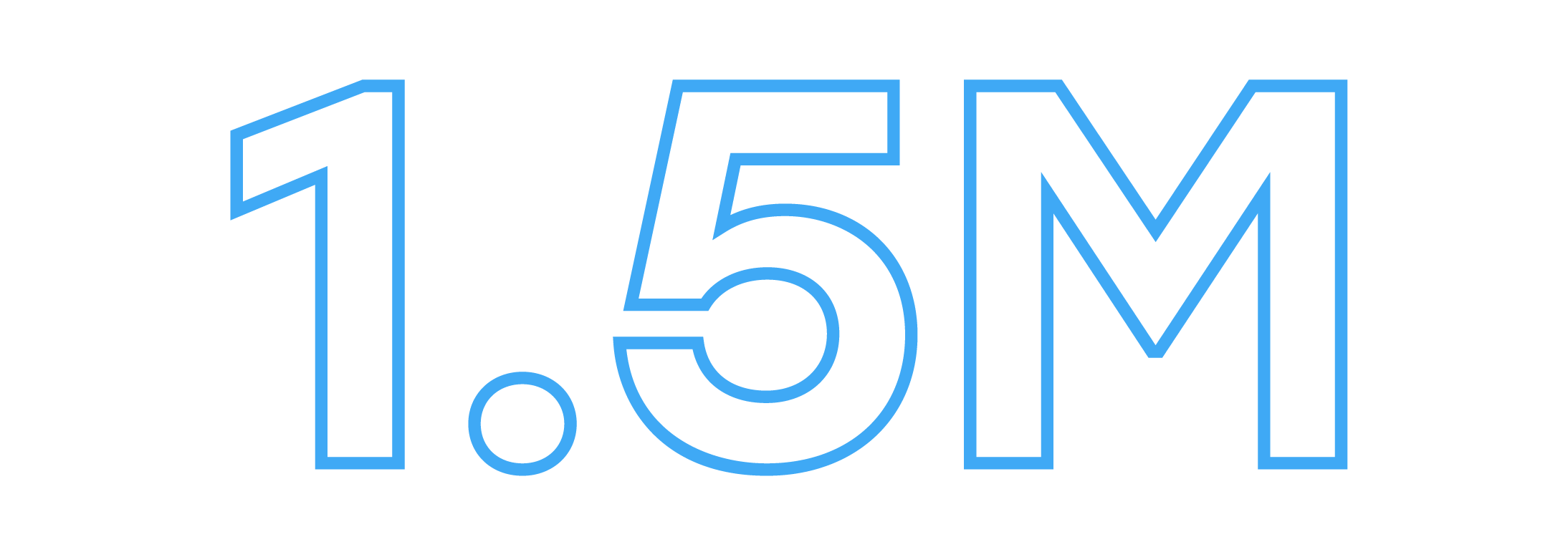

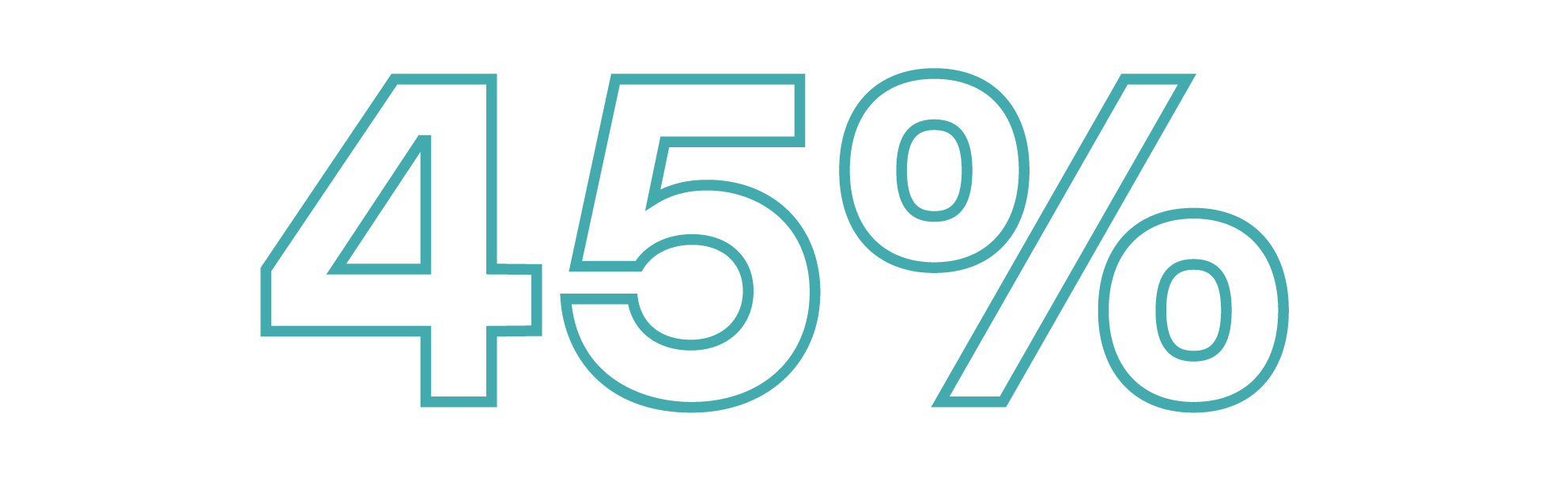

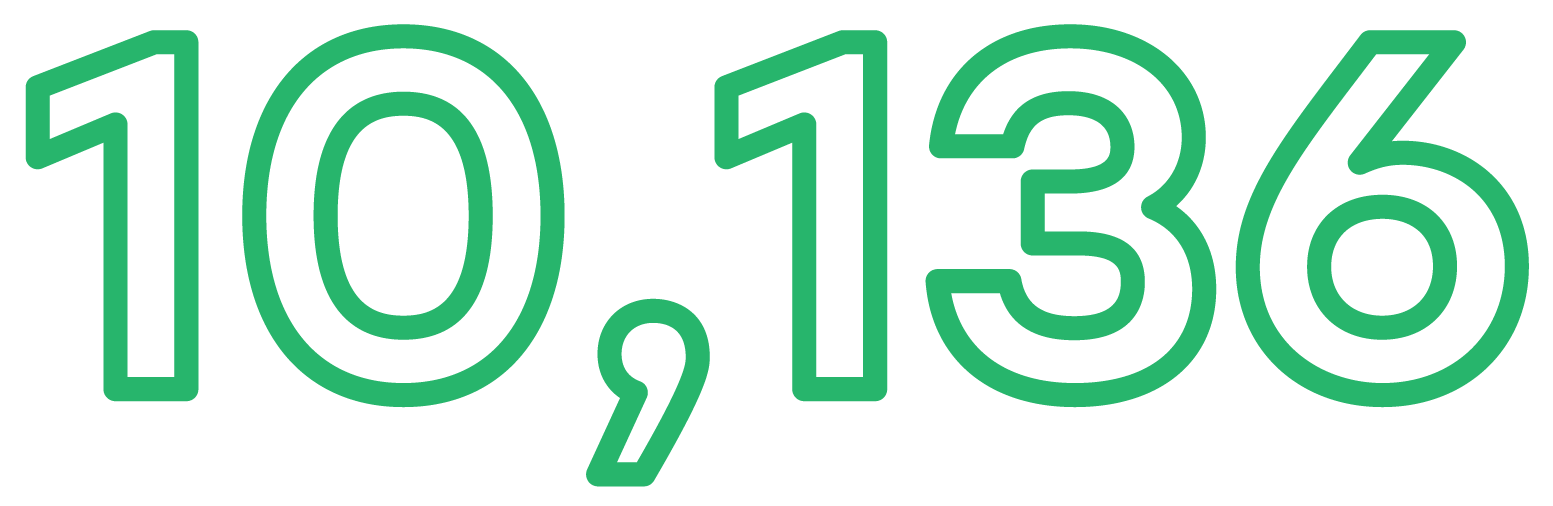

Waste Zero Activities in 2024

Trainings and presentations

Site visits and consultations

Tabling events

Facility tours

Local Action, Lasting Change

We work hand-in-hand with communities to bring circular practices to life — from sports teams to city streets. These partnerships help create scalable models for sustainability that start locally and grow outward.

Challenging Perspectives Through Creative Collaboration

Recology’s Artist in Residence (AIR) Programs invite local artists to transform discarded materials into inspiring works of art. Since 1990, these programs have connected creativity with sustainability through exhibitions, tours, and community engagement. Now active in seven locations, AIR reaches thousands each year—reimagining waste and reshaping how we see our world.

Backing the Sacramento Kings’ Sustainability Goals

As the official Sustainability and Zero Waste Partner of the Sacramento Kings through the 2027–28 season, Recology provides expert waste, recycling, and composting services at Golden 1 Center and Downtown Commons — supporting the Kings in meeting their sustainability goals with reliable, high-impact solutions.

Combatting Single-Use Waste in Petaluma

Recology Sonoma Marin teamed up with the NextGen Consortium to pursue the nation’s first citywide reusable cup program. Customers used purple bins to return cups, and Recology recycled cups that could no longer be reused at our material recovery facility. The pilot demonstrated reuse can work at scale and cut single-use waste.

Interested in a free consultation for your business or community group?

We work hand-in-hand with businesses and communities to help support your waste diversion goals. Contact your local Recology Customer Service team to schedule a meeting.